Leading change

Light at the end of the tunnel for SA’s energy-poor communities

The rate of burn deaths in South Africa is higher than anywhere else in Sub-Saharan Africa, at 8.5 deaths per 100 000 people, and higher than the global average too. Also alarmingly high are the rates of illness and premature deaths linked to indoor pollution from the burning of “dirty” fuels like paraffin and kerosene. These fuels are also often implicated in home and community-wide conflagrations and the consequent burn injuries.

Community visit to the Unisa demonstration site

Light at the end of the tunnel for energy-poor communities, especially in informal settlements where fires and indoor pollution are rife, is the work that a team of Unisa and South African Medical Research Council (MRC) researchers are doing to energise communities—cleanly, safely and affordably.

They have built live demonstration facilities at the south Johannesburg premises of Unisa’s Institute for Social and Health Sciences, where community members can experience for themselves the power of three clean-energy solutions for households: solar, biogas and cool coatings.

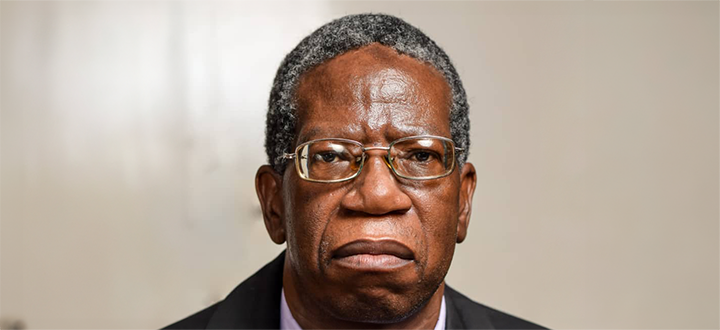

“When you tell people about how well alternative energies can work, they don’t believe you. This is why it’s important to have live facilities—an ‘energy village’—where people can see for themselves,” says the MRC’s David Kimemia.

Unisa’s Energy Project Team: Ralph Muvhiiwa (Material and Process Synthesis (MaPS) unit, Unisa), David Kimemia (MRC), Prof Ashley van Niekerk (MRC), and Ursula Lau (Researcher: ISHS).

Cleaner, cheaper, better energy

The energy village is the MRC-Unisa team’s response to the energy-poverty crisis plaguing millions of South Africans, who resort to burning combustible, highly polluting fuels for heating and cooking, often using cheap, unstable and leaky appliances.

The result is a double threat: out-of-control shack fires that regularly devastate lives and property in informal settlements around the country, and a high risk of illness and death from inhaling toxic smoke from indoor fires.

“Between 2009 and 2012, fire services responded to 5 000 informal settlement fires, and there are 3 500 burn deaths a year in South Africa,” says Professor Ashley van Niekerk of the MRC, adding that children and adult males tend to be the main victims.

The health effects of breathing in pollution from indoor fires range from pneumonia and lung cancer to asthma, ear infections, cataracts and acute lower respiratory infections. Globally, toxic smoke from indoor fires is now responsible for more premature deaths than HIV/Aids, malaria and tuberculosis, according to figures from the International Energy Agency.

What works and what doesn’t?

Clean-energy options are available in the marketplace but research is needed to identify what works and what doesn’t. This is the purpose of the three clean-energy solutions being piloted at the Unisa Institute for Social and Health Sciences.

“Different communities have different needs and so could benefit from different technologies. This is why we have two biomass technologies, a gasifier using plastic and paper waste, and a biodigester that consumes cow dung from farming,” says Ralph Muvhiiwa of Unisa’s Material and Process Synthesis (MaPS) unit, which is a partner in the community energy project.

The gasifier that converts plastic and paper waste into syngas is probably better suited to the needs of people living in informal settlements, while the cow dung-fuelled biodigester—which produces methane gas—lends itself to use in farming communities.

“Yes, methane is a greenhouse gas but we are harnessing it for household use and converting it into CO², which is 24 times less harmful than methane,” says Muvhiiwa. “If you just leave cow dung lying around, on the other hand, the methane is emitted into the atmosphere.”

Calculating costs and financing models

The research team is well aware that energy costs are a major factor for low-income communities, which is why they are exploring costs and financial models as part of the project.

The biggest cost associated with a community energy project would be buying the equipment and associated appliances. For instance, the team estimates that it would cost about R50 000 to set up a solar system to power five shacks in an informal settlement. This would be over and above the cost of appliances such as kettles, stoves and television sets.

Similarly, the cost of building a biodigester made of bricks, mortar and a bio bag would be in the region of R20 000. The main cost here would be the bio bag, as this is not available locally and has to be imported from China.

Once any of the systems are up and running, they cost very little to run. The fuel that feeds them (sun, paper and plastic or cow dung) is virtually free, and maintenance costs are negligible. For example, the solar home system would need some new batteries every few years or so, which is relatively inexpensive.

“We are designing a financial model to make energy provision sustainable, and we are speaking to corporate social responsibility partners,” says the MRC’s Kimemia. “But we are not promising anything for free, and communities will also have to bring something to the table.”

That is some time in the future, though, as the project is still in its first phase: assessing the technologies—and local communities’ responses to them—at the demonstration site. Only later will the team go out to energy-poor communities to explore controlled implementation.

In the meantime, the three systems are doing their job well, says Kimemia. “The biogas is performing optimally and boils one litre of water in three-and-a-half minutes compared to LPG which does the same task in five minutes. The cool coatings lowers the indoors temperature by between three and five degrees. The solar system is also performing well, although there is a need for extra batteries to store more power.”

There’s light at the end of the tunnel for energy-poor communities.

ISHS demonstration site where community members can experience the power of three clean-energy solutions for households: solar, biogas and cool coatings

*By Clairwyn van der Merwe

Publish date: 2017-05-12 00:00:00.0

Unisa honours Dr OK Matsepe's enduring legacy

Unisa honours Dr OK Matsepe's enduring legacy

Great strides towards concretising Unisa-PMC partnership

Great strides towards concretising Unisa-PMC partnership

Mental health among men in the workplace needs more attention

Mental health among men in the workplace needs more attention

"I owe everything to Unisa and my late supervisor's priceless mentoring"

"I owe everything to Unisa and my late supervisor's priceless mentoring"

Majikijela - a queer scholar raising homosexuality awareness through his work

Majikijela - a queer scholar raising homosexuality awareness through his work